Add to Cart

High precision SLA rapid prototyping technology

Professional high-accuracy light-curing 3D printing model equipment, using SLA light curing technology, can help you reduce the production cost of hand model, improve production efficiency, and achieve unprecedented accuracy, surface quality, material type, reliability, stability, etc. Promote.

Batch printing, development efficiency increased by more than 5 times

Using galvo scanning technology and variable spot technology, with ultra-fast print speed. One-time batch production of multiple products increases the development efficiency of the entire industrial design field by more than 5 times. Usually, the CNC needs to complete the product in one week, and Yizhi 3D printer can be completed in 1-2 days.

Difficult to ignore, accuracy 0.05mm

360 ° no dead angle printing, easy to make barbs, curved surfaces, hollow and other precision model molds. Accurate height of 0.05mm, dandelion hairy feeling can also be produced. This provides a more reliable form factor and functional verification for industrial design.

Zero noise, low energy consumption, more environmentally friendly

There is no significant mechanical movement, no noise, and less noise than whispers. The maximum power consumption of a large-scale 3D printer is less than 2 kW, which is lower than the power of the induction cooker. With the continuous popularization of 3D printing, the dust pollution of CNC processing and the heavy metal pollution of etching processes have been effectively controlled. Its environmental protection and energy saving features have made significant contributions to the human environment and have been one of the key support projects of the National 2025 Plan, becoming an innovator in the era of Industry 4.0.

Multi-attribute materials reduce manufacturing costs by more than 50%

Multi-attribute raw materials, including hard materials, soft materials, elastic materials, transparent materials, high-temperature materials, and high-strength materials, meet the needs of different industries. The constant updating of materials also reduces the production costs, especially for products with complex structures. For example, a small mineral water bottle hand board, the traditional industry needs to meet the surface and transparent effects, the cost more than 5,000 yuan, while the 3D printing is only less than 500 yuan.

Easy to operate, unmanned 24 hours

The matching control software has a simple interface and the novice can master the operation method within 3 days. Full computer production, no need for manual guards, 24-hour unmanned intelligence. This allows industrial manufacturing to save about 60% of the human cost, and is no longer dependent on the master, no need to worry about personnel loss.

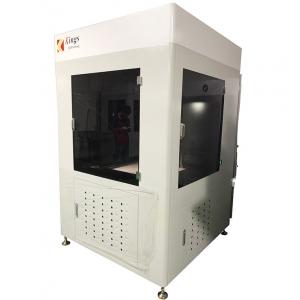

stereolithography 3d printer